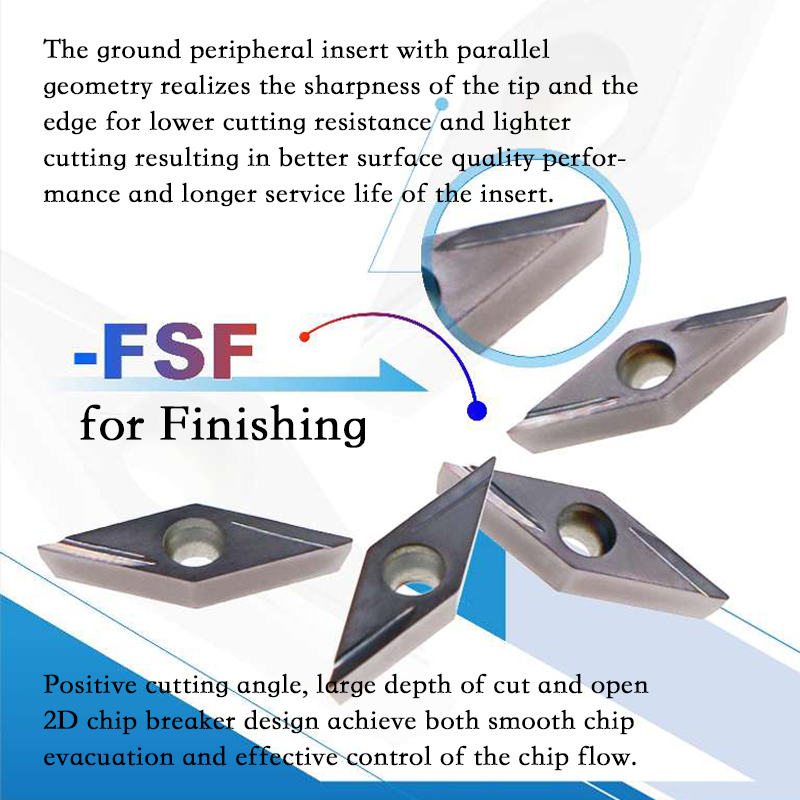

The ground peripheral insert with parallel geometry realizes the sharpness of the tip and the edge for lower cutting resistance and lighter cutting resulting in better surface quality performance and longer service life of the insert.

FSF-for finishing

Positive cutting angle, large depth of cut and open 2D chip breaker design achieve both smooth chip evacuation and effective control of the chip flow.

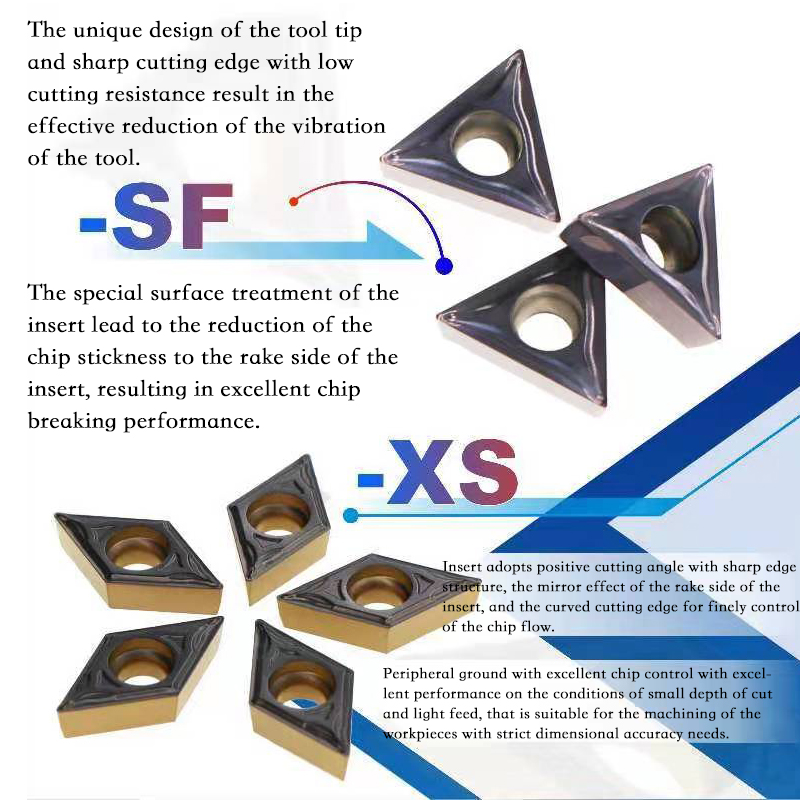

-SF for Finishing

The unique design of the tool tip and sharp cutting edge with low cutting resistance result in the effective reduction of the vibration of the tool.

The special surface treatment of the insert lead to the reduction of the chip stickness to the rake side of the insert, resulting in excellent chip breaking performance.

-XS for Finishing

Insert adopts positive cutting angle with sharp edge structure, the mirror effect of the rake side of the insert, and the curved cutting edge for finely control of the chip flow.

Peripheral ground with excellent chip control and excellent performance on the conditions of small depth of cut and light feed, which is suitable for the machining on the work pieces with strict dimensional accuracy needs.

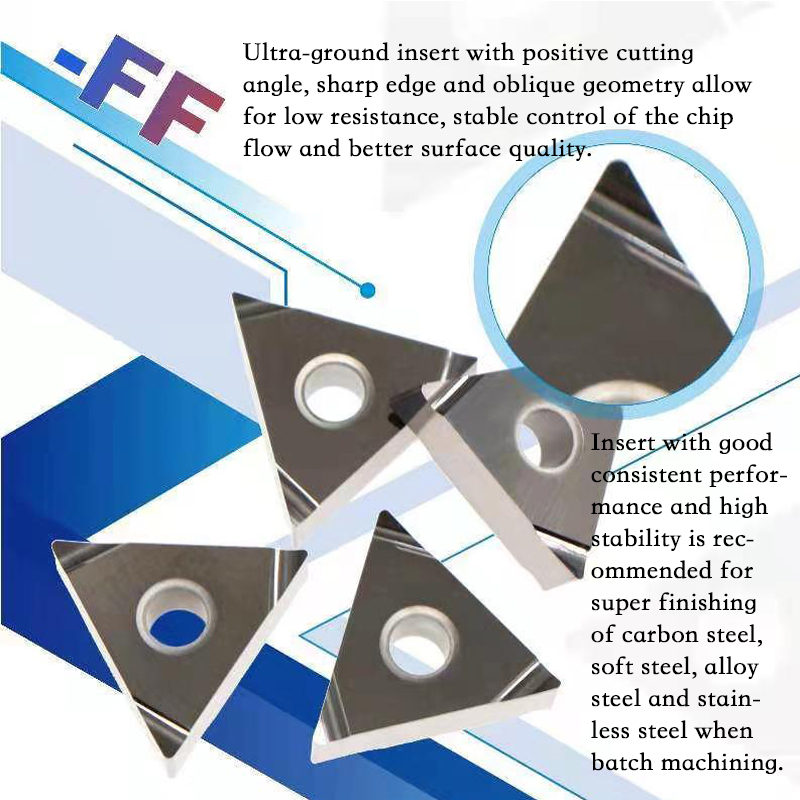

-FF for Super Finishing

Ultra-ground insert with positive cutting angle, sharp edge and oblique geometry allow for low resistance, stable control of the chip flow and better surface quality.

Insert with good consistent performance and high stability is recommended for super finishing of carbon steel, soft steel, alloy steel and stainless steel when batch machining.

BT Series for Complicated Bearing Parts Machining

The effective cutting edge can reach up to 5.0 mm, with 3 angles to meet the special requirements of various component solutions.

The optimized geometry effectively controls the chip flow and avoids the chip entanglements.

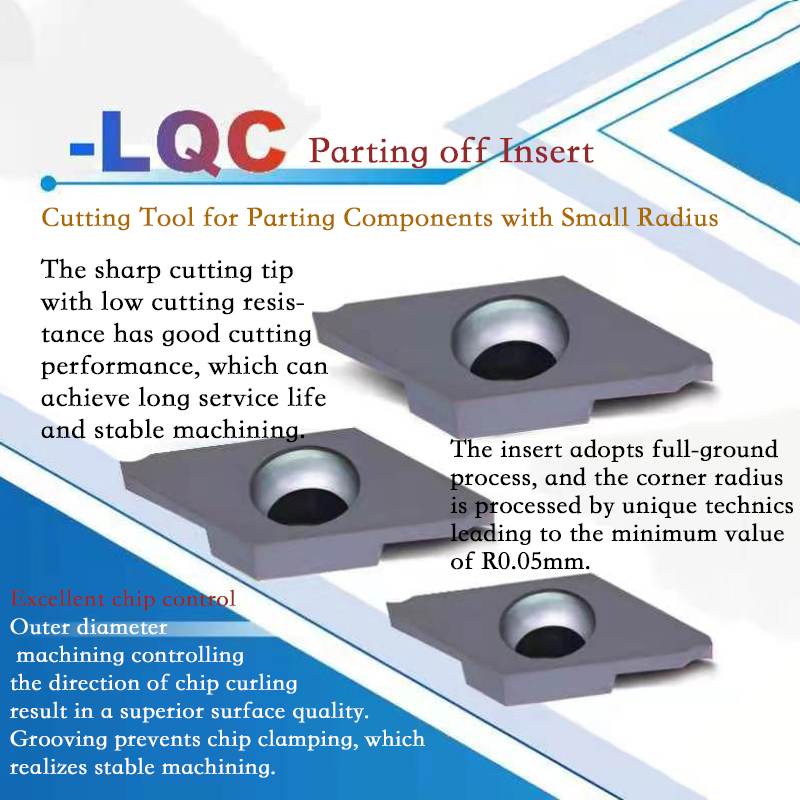

-LQC Parting off insert

Cutting tool for parting components with small radius

The sharp cutting tip with low cutting resistance has good cutting performance, which can achieve long service life and stable machining.

The insert adopts full-ground process, and the corner radius is processed by unique technics leading to the minimum value of R

Excellent chip control

Outer diameter machining controlling the direction of chip curling result in a superior surface quality.

Grooving prevents chip clamping, which realizes stable machining.

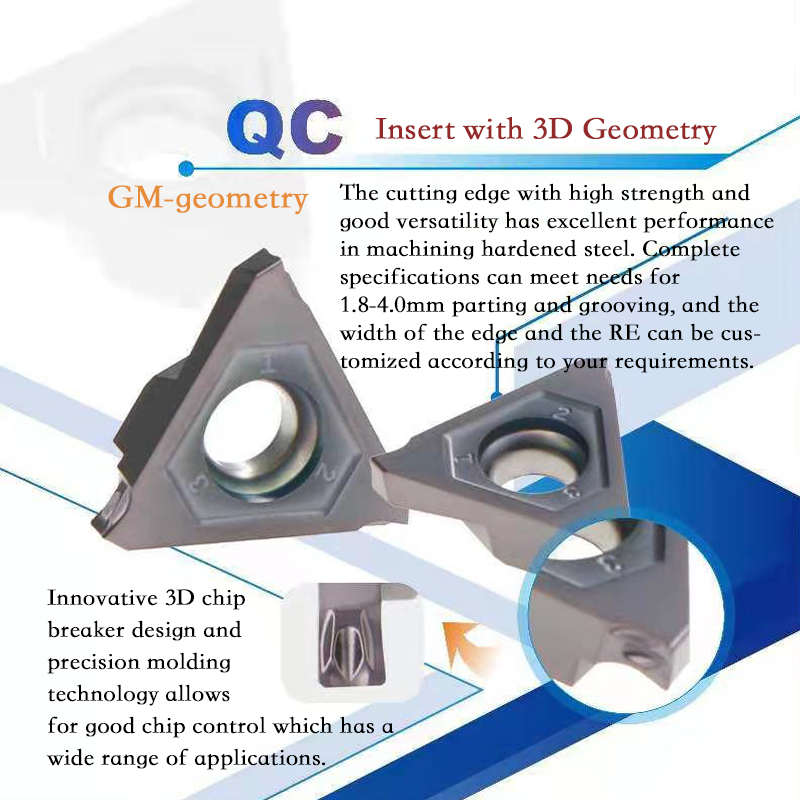

QC Series -Geometry

The cutting edge with high strength and good versatility has excellent performance in machining hardened steel. Complete specifications can meet needs for 1.8

Innovative 3D chip breaker design and precision molding technology allows for good chip control which has a wide range of applications.

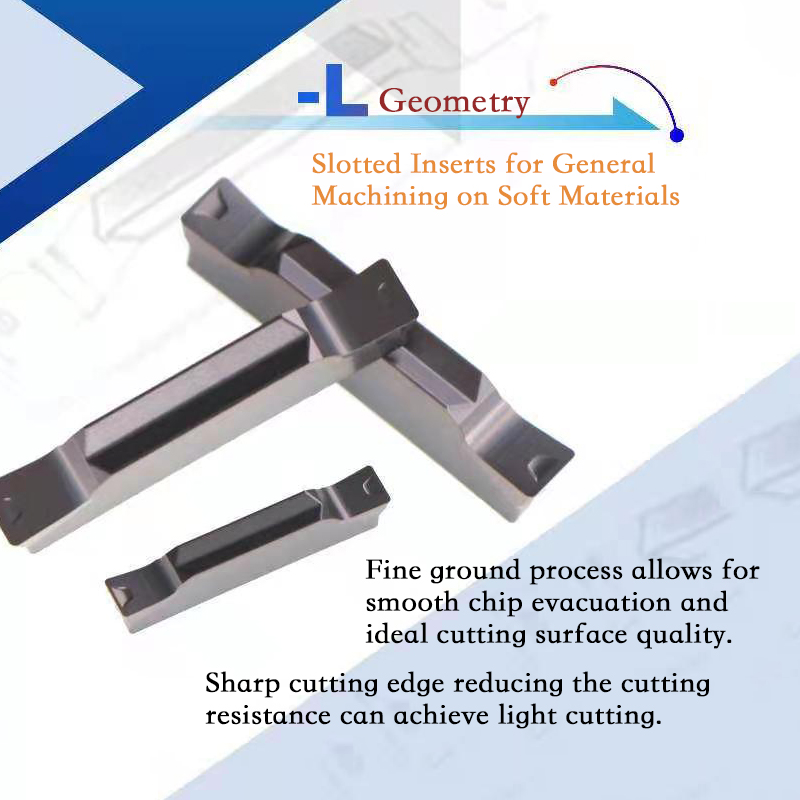

-L Geometry

Slotted inserts for general machining on soft materials

Fine ground process result in smooth chip evacuation and ideal cutting surface quality.

Sharp cutting edge reducing the cutting resistance can achieve light cutting.

.

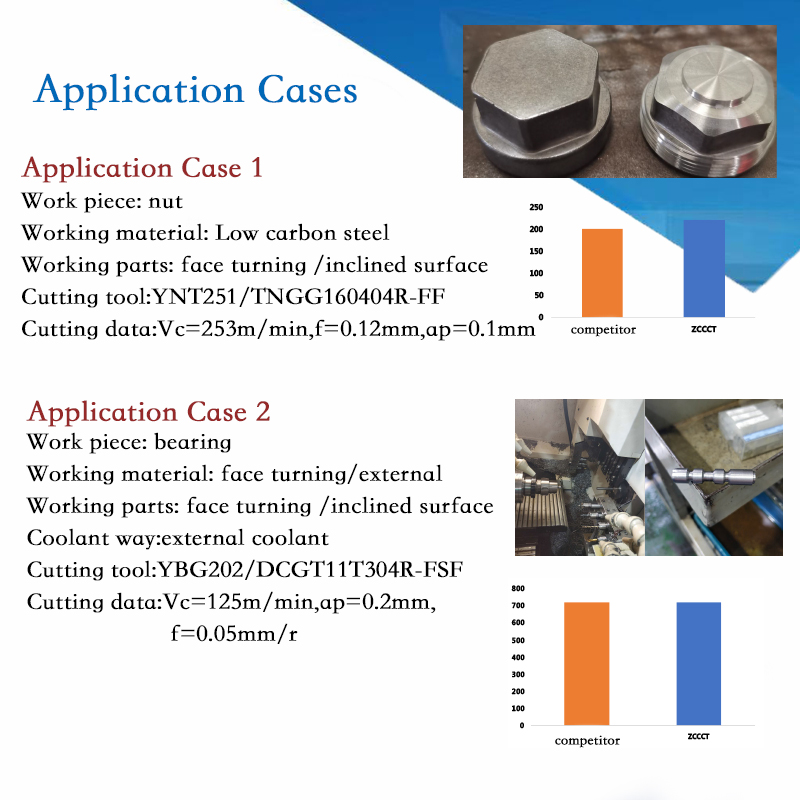

Application 1

Work piece: nut

Working material: Low carbon steel

Working parts: face turning /inclined surface

Cutting tool: YNT251/TNGG160404R-FF

Cutting data: Vc=

Work piece: bearing

Working material: face turning/external

Working parts: face turning /inclined surface

Coolant way: external coolant

Cutting tool:YBG202/DCGT11T304R=FSF