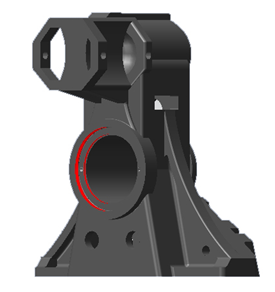

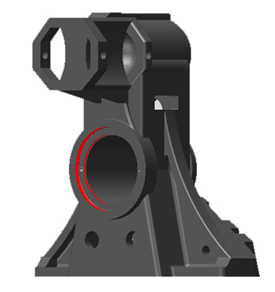

With the ever-increasing requirements of customers for heavy vehicle performance and applicability, automotive enterprises have accelerated product upgrading pace and product components structure becomes more complex. Balance support is one of such parts, with complex bracket shape structure, and certain difficulty in machining.

The material of the auto balance bridge in this paper is ZG270-500 (HB180-260), with complex appearance, high machining difficulty. The following introduces the cutting tools and related recommended cutting data applied in product processing. Different parts of the same type operation are not repeated.

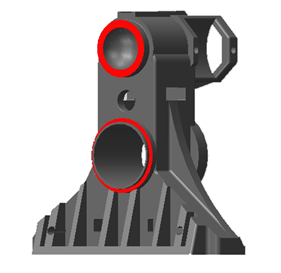

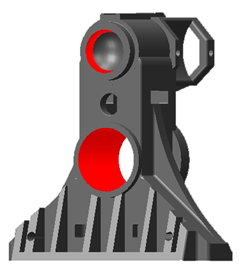

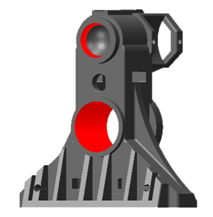

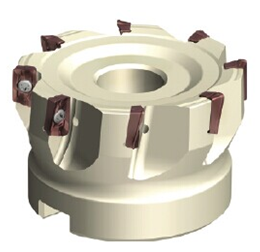

Rough milling

hole end face

Tool:FMP02-160-C40-SE12-12

Insert:YBC302/SEET120308PER-PR

Cutting speed: Vc=

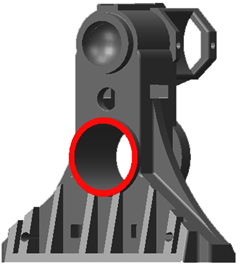

Rough boring

Tool:RB04-CN63-87115-110L

Insert:YBC252/CCMT120408-HR

Cutting speed:Vc=

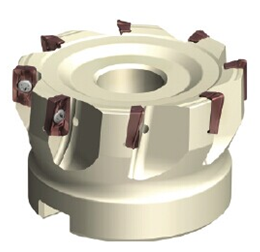

Finish milling

hole end face

Tool:FMP02-160-C40-SE12-12

Insert:YBC302/SEET120308PER-PF

Cutting speed: Vc=

Finish boring

Tool:FB04-CN63-87134-110L

Insert:YNG

Cutting speed:Vc=

Interpolation

milling hole

Tool:EMP02-050-A22-AP11-06

Insert:YBC302/APKT11T308-PM

Cutting speed:Vc=

Interpolation

milling step surface

Tool:EMP12-050-A22-AZ11-07

Insert:YBG205/AZGT113508PDER-PF

Cutting speed:Vc=

Drilling 2-?5

hole and chamfering

Tool:(非標鉆頭)D5.0 鉆深10 倒角

Cutting speed: Vc=